Aluminum Extrusion Profiles – Why Use Aluminum Framing?

In the arena of industrial design, aluminum extrusion profiles stand as a testament to modern engineering’s capability and adaptability. The intricate process of extruding aluminum into detailed profiles provides a myriad of advantages for a range of applications. As industries evolve, there’s a growing demand for materials that can be both resilient and malleable. Aluminum framing, due to its unique characteristics and extrusion techniques, can meet these demands.

In the arena of industrial design, aluminum extrusion profiles stand as a testament to modern engineering’s capability and adaptability. The intricate process of extruding aluminum into detailed profiles provides a myriad of advantages for a range of applications. As industries evolve, there’s a growing demand for materials that can be both resilient and malleable. Aluminum framing, due to its unique characteristics and extrusion techniques, can meet these demands.

Understanding the Fundamentals of Aluminum Extrusion Profiles

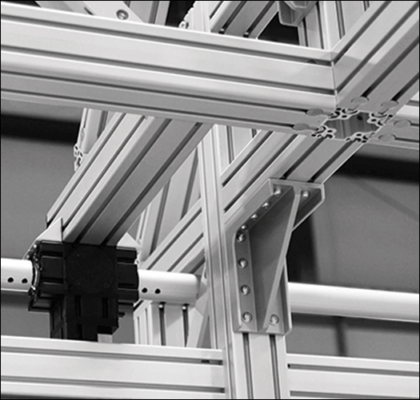

Extrusion aluminum profiles are created by pushing billets of aluminum through a pre-designed die. This method shapes the aluminum into precise, continuous lengths with uniform cross-sectional profiles. This process is advantageous because it allows for complex, multi-functional shapes that can then be used in a myriad of applications. The resulting forms can range from simple bars or tubes to intricate rails or custom frames.

Aluminum’s natural properties, combined with the extrusion process, offer profiles that are lightweight yet strong. The inherent strength-to-weight ratio of aluminum ensures that while these profiles are light, they don’t compromise on robustness. Furthermore, the extrusion process gives manufacturers flexibility in design, ensuring that specific requirements for various projects can be met efficiently.

The Unique Benefits of Aluminum as a Framing Material

Aluminum, as a metal, boasts a set of characteristics that make it ideal for framing. It’s resistant to corrosion, ensuring longevity even in challenging environments. Plus, its ability to conduct heat and electricity, paired with its non-magnetic nature, offers additional advantages in certain applications. Being one-third the weight of steel, yet maintaining obvious strength, makes aluminum a preferred choice in industries where weight constraints are pivotal.

Another distinctive advantage of aluminum is its recyclability. Being 100 percent recyclable, aluminum loses none of its original properties during the recycling process. This ensures that businesses align with sustainability goals, reducing their carbon footprint. In addition, the aesthetic finish of aluminum framing, combined with its resistance to rust, makes it a popular choice for visible structures.

Versatility and Applications of Aluminum Extrusion Framing

The use of aluminum extrusion framing extends across a variety of industries. In the construction sector, it’s chosen for window frames, doorframes, and facades, given its resilience and elegant finish. Transportation industries, particularly aerospace and automotive, value aluminum for its lightweight nature, which can significantly enhance fuel efficiency. Even in the realm of electronics, aluminum’s conductivity and heat dissipation qualities find utility.

Furthermore, aluminum framing can be tailored to fit specific industry needs. Whether it’s for structural supports in architecture or rails in transportation systems, the adaptability of extruded aluminum profiles ensures they meet specific criteria. The end result is a robust structure ensuring efficiency and longevity.

Comparing Aluminum Framing to Other Industrial Materials

While steel remains a popular choice in the construction and industrial sectors, aluminum framing provides advantages that are hard to overlook. The strength-to-weight ratio of aluminum outshines steel, making it preferable for applications requiring lighter materials. Next, aluminum’s natural resistance to rust and corrosion gives it an edge, especially in applications exposed to elements.

When compared to plastics or other materials, aluminum stands out due to its recyclability and structural integrity. While plastics might offer weight advantages, they often can’t match the mechanical strength of aluminum. Furthermore, environmental concerns associated with plastic make aluminum, which is totally recyclable, a more sustainable choice for forward-thinking businesses.

Contact Industrial Profile Systems To Maximize Aluminum Extrusion Profiles and Aluminum Framing

The advantages of aluminum extrusion profiles and aluminum framing in industrial applications are clear. From adaptability and strength to sustainability and aesthetics, this is the premier choice. If you’re looking to incorporate aluminum profiles in your projects or seeking guidance on their applications, count on Industrial Profile Systems. Our team of experts is dedicated to ensuring you harness the full potential of aluminum in your endeavors. Contact us today!