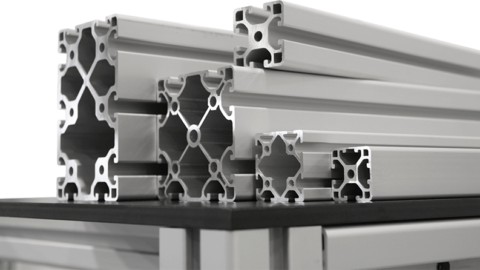

Aluminum extrusion, or T-slot extruded profile, is an amazing material for building a wide variety of frames and structures. However, we are the first to admit there are more than a few aluminum extrusion profile manufacturers competing for your business.

Aluminum extrusion, or T-slot extruded profile, is an amazing material for building a wide variety of frames and structures. However, we are the first to admit there are more than a few aluminum extrusion profile manufacturers competing for your business.

By discussing the five most important considerations, this blog will help you decide who to work with. If, after reading this, you still have questions, contact us for the answers and information you need.

Top 5 Factors to Consider When Selecting Aluminum Extrusion Profile Manufacturers

#1. Material Quality

Assuming you’re concerned about how parts go together, how your design functions and what it looks like, you want to use the best quality extruded aluminum. This means high-grade and dimensionally consistent alloy. When speaking with aluminum extrusion profile manufacturers, ask what series alloy they use and what tolerances they can maintain.

At Industrial Profile Systems our profile is extruded from 6060 series and meets the tolerance standards set by DIN EN 12020-2. This ensures that whatever you build with our section will go together easily and perform the way you need.

#2. Parts Catalog

Your design shouldn’t be constrained by a limited range of profiles and accessories. This is why you should check what a potential supplier has in their catalog. Look for different weights of section to suit the loads expected in the application, and a wide range of shapes and sizes. While you’re at it, satisfy yourself there are enough different feet, wheels, handles, hinges and so on to let you build exactly what you want.

Our catalog covers both inch and metric profile, with three light, medium and heavy-duty weights to suit the needs of your project. We offer over 210 different T slot profiles and an extensive list of parts to help you complete your designs.

#3. Availability of Technical Support

Building with extruded aluminum profile is straightforward, but there may be times when you’re not sure of the best way of doing something. Likewise, it may suit you better to give a specialist a sketch of what you want and let them take care of the detail design.

In both these situations you want to work with a vendor who can give you the technical support you need. At IPS our product specialists have a lot of experience with our profile and they can help with your design. Better still, we offer a no-cost engineering service where we’ll do the detail design work and produce the parts list for you.

#4. Delivery Performance

One reason for working with extruded aluminum profile is the speed with which you can turn ideas into reality. When speaking with aluminum extrusion profile manufacturers, ask about delivery times.

At IPS we ship parts from stock in 1–2 days. Complete assemblies typically take 2–3 weeks, although this depends on the size and complexity of what we’re building.

#5. Ability to Handle Dynamic Applications

Some engineers have concerns about using extruded aluminum in applications with motion. This may be a result of a negative experience when using inexpensive materials. We specialize in dynamic solutions and we’re very experienced at integrating linear motion into machines. Our heavy-duty profile line, combined with the strict dimensional tolerances on profile rails, give our systems high repeatability and durability, plus speed and accuracy.

Partner With Professionals

Aluminum profile is not all the same, and neither are the aluminum extrusion profile manufacturers. Before choosing a vendor, make sure they have the skills, backup and product quality you need. Failing to do so may result in a structure that doesn’t last or function the way you need. For more advice, contact us and let’s talk.