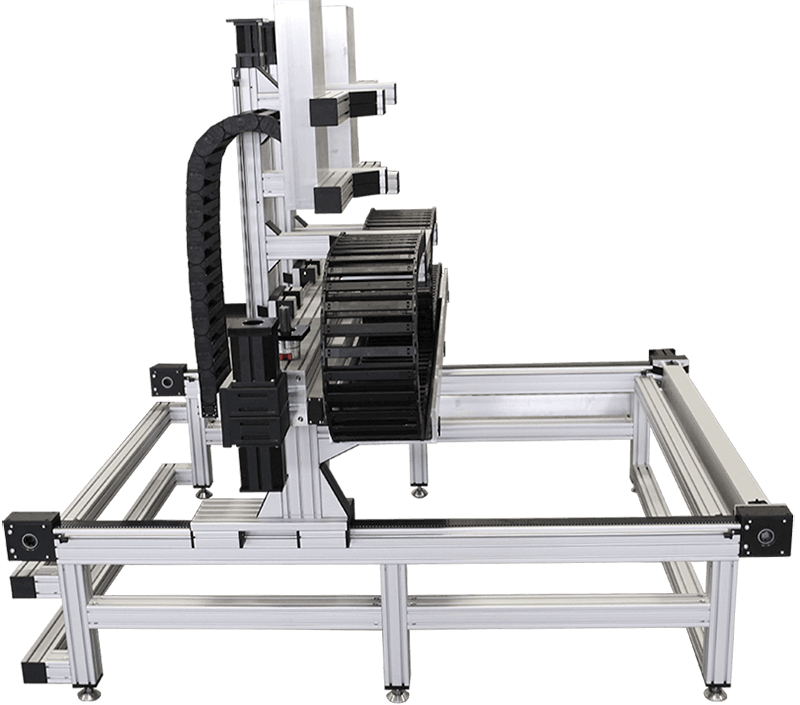

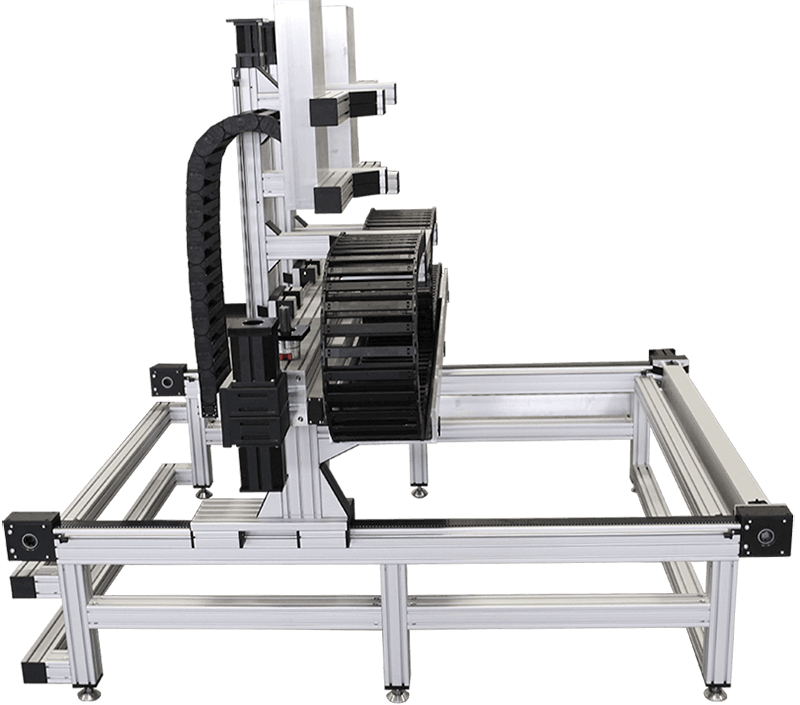

Industrial Profile Systems’ dynamic linear motion selection includes a variety of high-quality extruded aluminum profiles, components and comprehensive linear motion systems. From light duty to heavy duty, with travel of a few inches to over 200 feet (60m), and loads of a few ounces to thousands of pounds. The IPS product line consists of a wide range of dynamic components for Industrial Profile Systems’ engineers to select from when designing a mechanical solution for your next linear motion project.

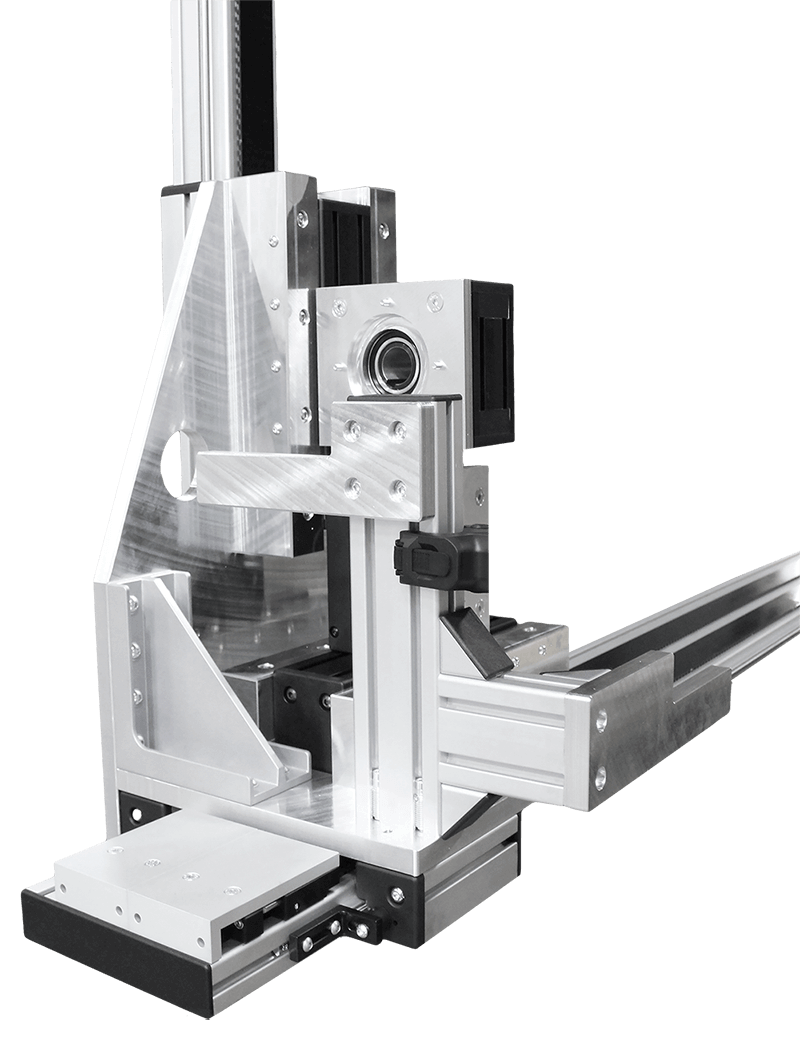

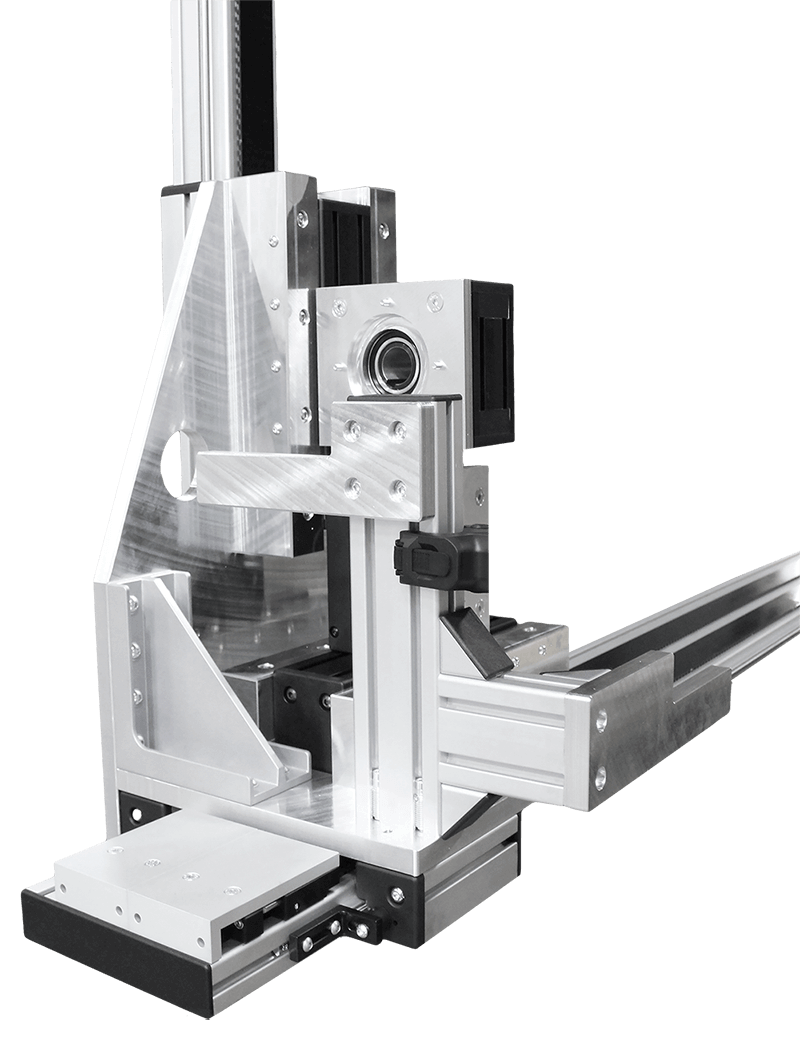

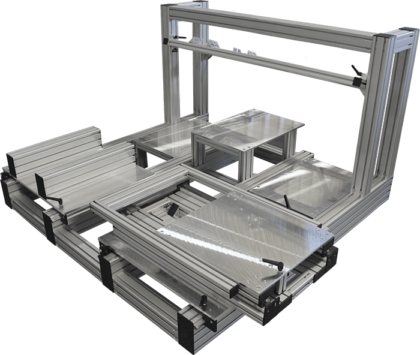

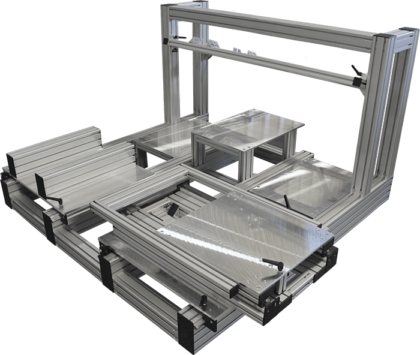

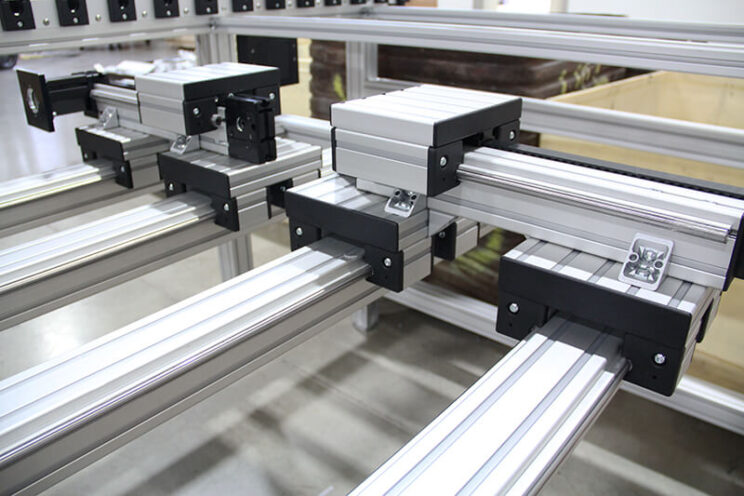

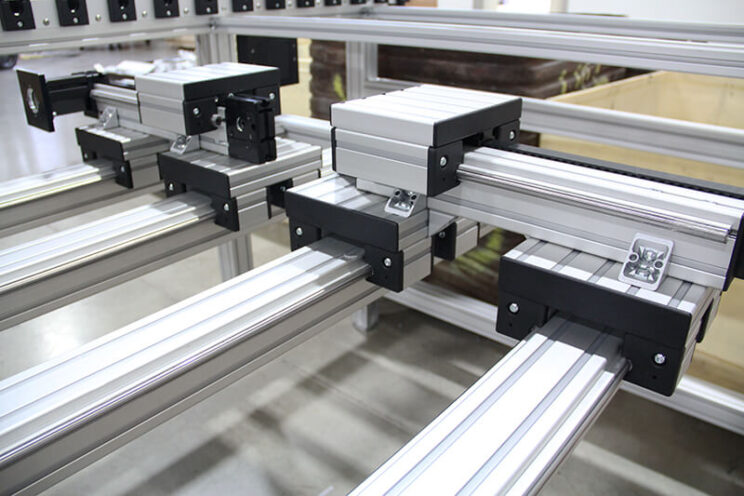

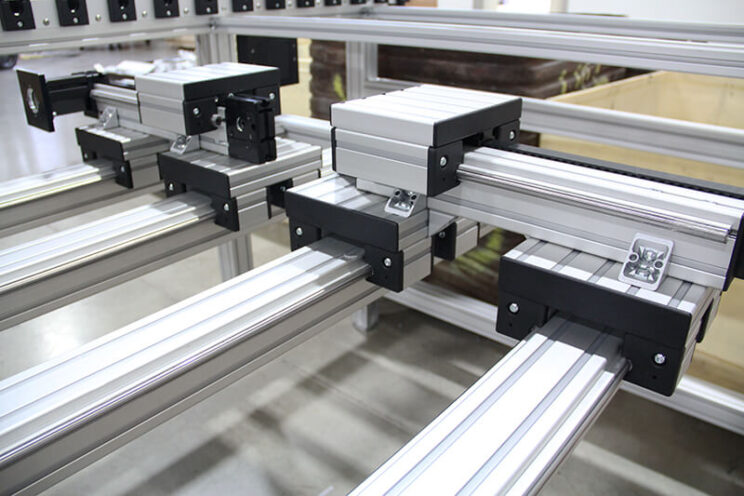

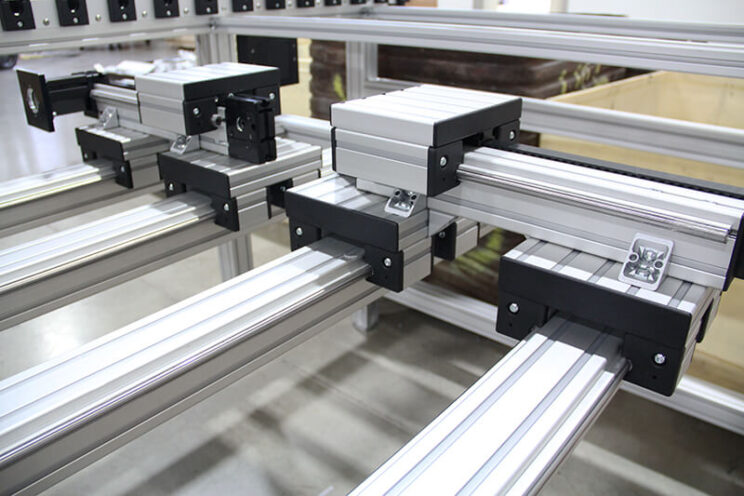

By taking advantage of the high straightness tolerance of the L8 extruded aluminum profiles, Shaft Clamp Profile is used enabling the installation of guide shafts into the standard T-slot grooves. This modularity is not only convenient for those looking to add motion capabilities to an existing frame, though it is particularly useful when designing and constructing large support structures for linear gantry applications.

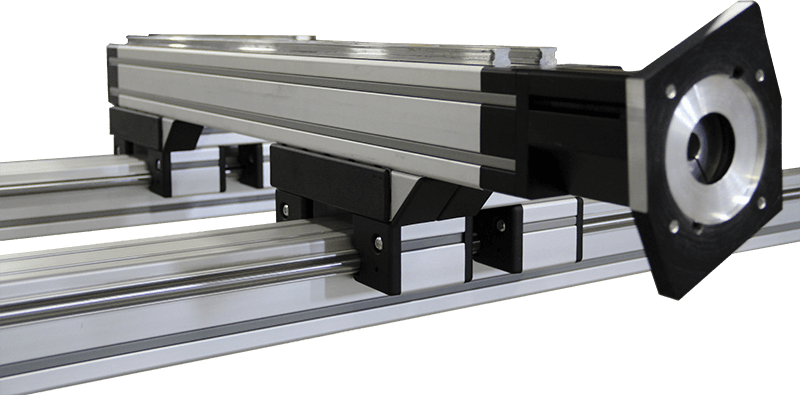

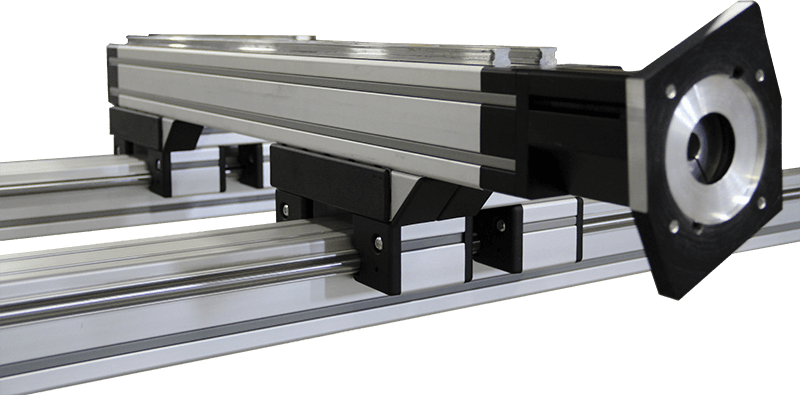

We offer easy belt-driven linear actuator solutions that are ideal for tight spaces without sacrificing precise movement. With traditional belt-driven linear actuator systems and ball-screw linear actuators we can build a tailored linear motion system by utilizing the extruded aluminum profiles and components. We build ball screw actuators up to 110 inches (2794mm) in length, available with 5 and 20-pitch screw. Learn more about our capabilities in belt-driven linear actuators.

Belt-Drive Guidelines

*Dependent upon project applications

Ball-Screw Guidelines

*Dependent upon project applications