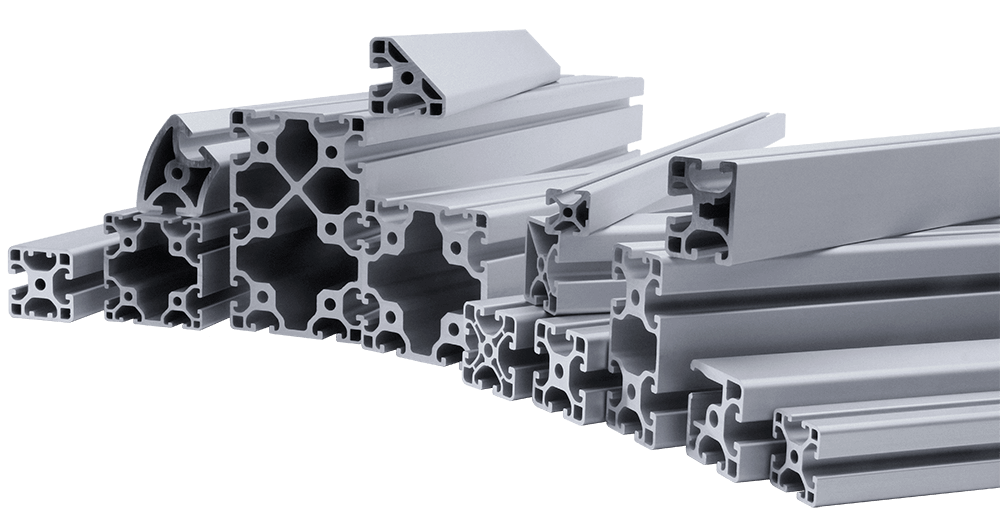

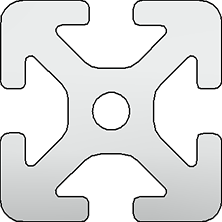

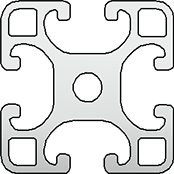

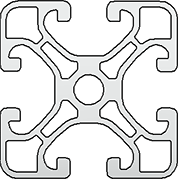

Extruded aluminum framing is aluminum alloy transformed into cross-sectional framing. It is commonly referred to as T slot profile. Inclined groove flanks make up the T-slot. Each profile line has flanks on at least one side. The groove extrusions enable modular design principles. Think of it as a building system that has infinite potential.

Ensure modular connections take advantage of the controlled elastic deformation. Doing so helps maximize the strength of each connection. All profiles come with an anodized or powder coat finish for ultimate protection levels.